Using a camera

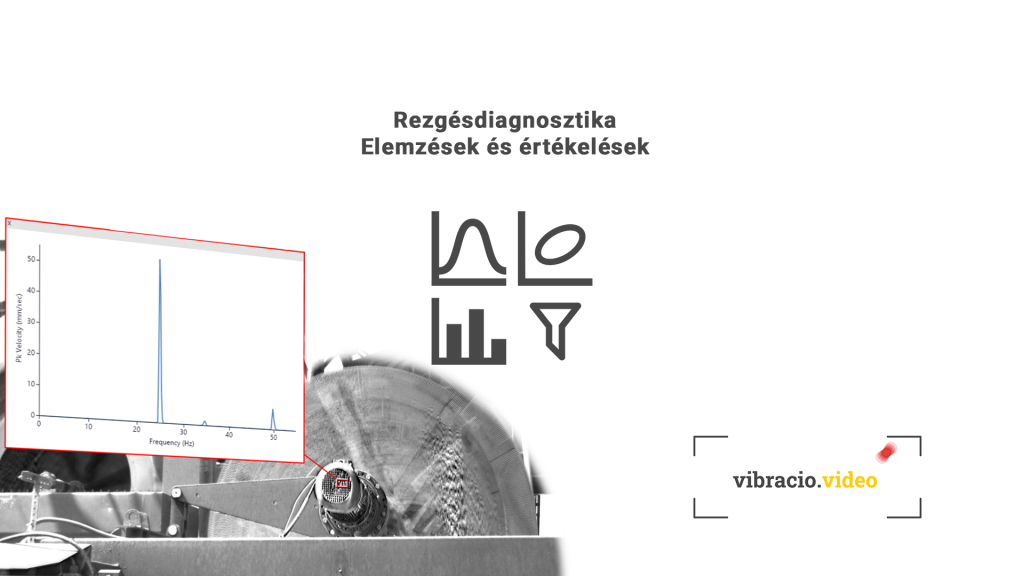

We can measure and visualize vibrations and movements that were previously not possible. Non-contact, with millions of sensors, simultaneously.

Please contact us if you need help in:

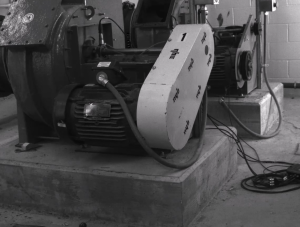

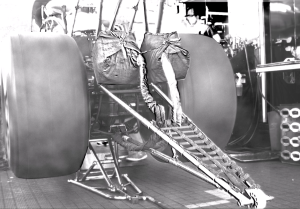

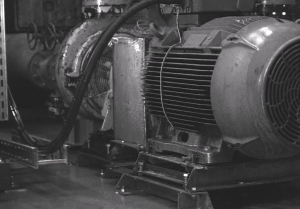

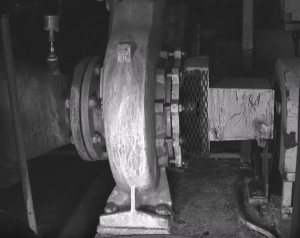

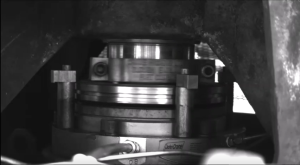

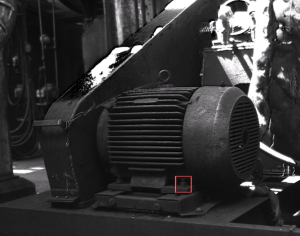

- Vibration diagnostics, vibration measurement: including electric motors, pumps, mixers, concrete foundations, lightweight and sensitive equipment,

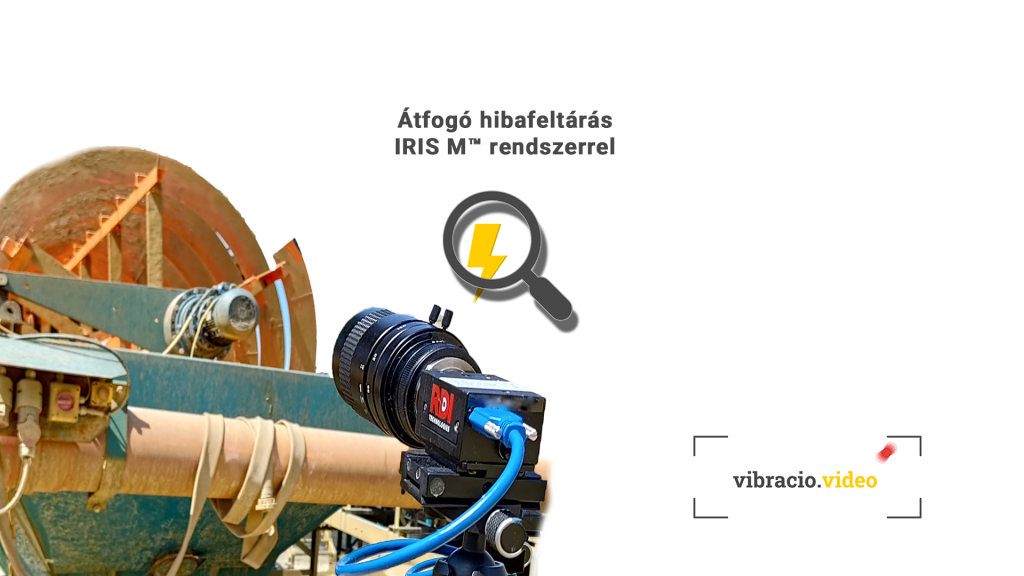

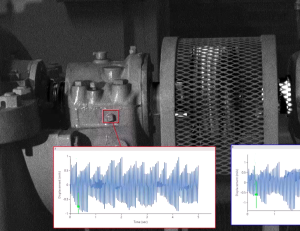

- Troubleshooting: we can find the root cause of faults by amplifying the recorded video,

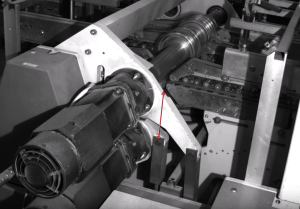

- Monitoring and process control: production equipment, production robots, milling and pressing machines, rolling mills

- Recording the initial condition of new equipment

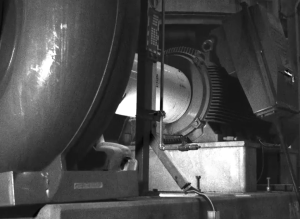

- Measurement of vibration in pipes and pipelines

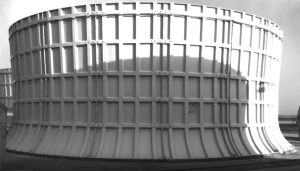

- Simultaneous vibration measurement of complex structures, large installations and buildings

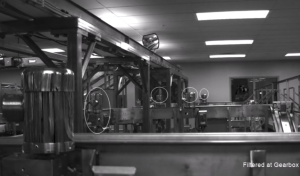

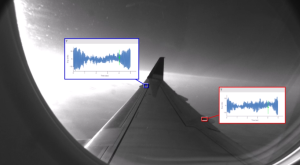

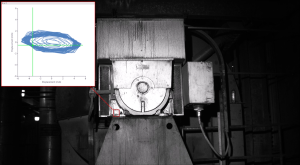

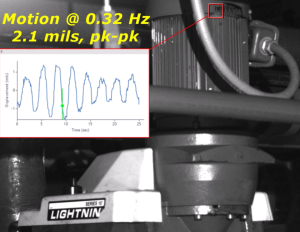

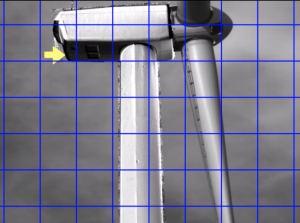

The Iris M™ system, based on video technology, uses a high-speed camera to record the vibrations, movements and processes to be measured, with each pixel in the recording capturing the data as a vibration sensor. The results are evaluated on the spot using Motion Amplification® technology.

Non-contact and safe, because it does not affect the operation of the equipment and does not expose the surveyors to danger, as the data is collected remotely by camera.

Non-contact and safe, because it does not affect the operation of the equipment and does not expose the surveyors to danger, as the data is collected remotely by camera. The measurement process is fast, with data collected from millions of points in a fraction of a second.

The measurement process is fast, with data collected from millions of points in a fraction of a second. We can identify the faulty elements and see which devices or equipment are moving abnormally, helping to identify the root cause of the fault – Root Cause Analysis.

We can identify the faulty elements and see which devices or equipment are moving abnormally, helping to identify the root cause of the fault – Root Cause Analysis. We can give you clear information, faults are easy to identify, just look at the Motion Amplification ® magnification video where you don’t have to browse through piles of data and complicated diagrams

We can give you clear information, faults are easy to identify, just look at the Motion Amplification ® magnification video where you don’t have to browse through piles of data and complicated diagrams We can help in many places, not limited by the conditions of use of conventional vibration sensors.

We can help in many places, not limited by the conditions of use of conventional vibration sensors.